Ferrari was one of the first teams to introduce their major

upgrade. On the second day of the second test in Barcelona, once the rain had

stopped we saw part of the upgrade package, as some more parts were tested in the

last day of the test and the rest of the parts will be tested tomorrow Friday

15/03/2013 during free practise of the Australian GP.

While the concept did not change, the new sidepods now bend

down more. As a result the coanda ramp is now lower to better aim the exhaust

plume towards the diffuser’s edge.

|

| New Sidepods |

|

| Old Sidepods |

As well as a changed coanda ramp, the cooling outlets have

changed. In the following drawings I

have moved the suspension and rear wing so that you can see what has changed

more easily.

|

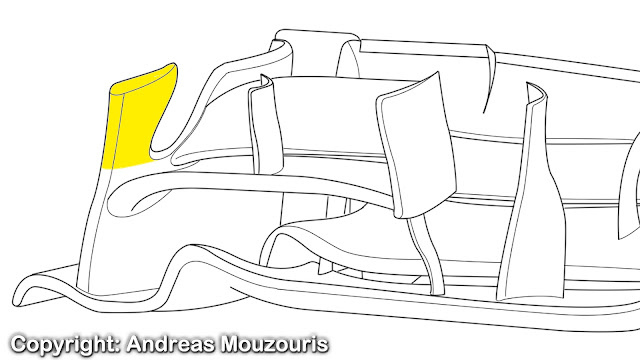

| New Cooling Outlets |

|

| Old Cooling Outlets |

The new version sports wider cooling outlets just behind the

exhaust and coanda ramp while in the older version they were slimmer. However,

in the original version which is very similar to the one present on the F2012,

there was a second cooling outlet further back which also featured two cut-outs

on each side. The second cooling outlet has now been removed, thus the need for

the wider outlets behind the exhaust.

|

| New |

|

| Old |

The new front wing was briefly seen on the second day of

testing and brought back for the last day.

This new front wing adds yet another element on its outer

tips, together with new cascade wings, endplates and the adjustable upper

element.

|

| New Front Wing |

|

| Old Front Wing |

The new element on the outer tips, allows the wing to curve

outwards at a larger angle to create more downforce and direct a larger portion

of the airflow around the wheels.

The new endplate is covering up a portion of the open area

that allowed airflow flowing over the top of the wing to flow to the outside.

This will create more downforce. As well as the new endplate, the footplate now

features a slot which is an innovation by Ferrari it is the first time seen on

a car, ever.

|

| New Front Wing Endpate |

|

| Old Front Wing Endpate |

The new cascade element is no longer divided into two

different parts, instead it is one winglet only much wider than before. The

fence that divided the two cascade elements on the older version has now become

a vertical fence which will induce a stronger vortex in the attempt two direct

the airflow around the front wheels as efficiently as possible.

At the top of the endplate a smaller winglet has been added,

similar to the one used by Red Bull.

The inner adjustable element of the wing has been revised,

with its inner extremities now taller than before.

Moving slightly upwards, we will find the new strake running

along the sides of the nose that was first introduced in the last day of the

first Barcelona test but was slightly revised in the second one. The strakes

are there for legality purposes, so they were tested before Melbourne.

On the last day of testing, the team tested more new parts.

On of which was the new rear wing. The wing now features smaller v-cutouts on

the top of the upper element. In addition, the endplate has been revised and

the gills are now slightly smaller than before. Those gills bleed the high

pressure air from the inside of the wing to the outside, reducing drag by

weakening the strength of the vortex shed at the wing tips.

The last new part tested was a new diffuser which still

features the airfoil shaped gurney flap on top of the diffuser’s trailing edge,

but it now curves downwards instead of stopping at the edges. Also, the

diffuser no longer dips down where the two main vertical strakes are located.